Googong Water Treatment Plant

The Googong Water Treatment Plant (WTP) was built in 1979 at the same time as Googong Dam.

The Queanbeyan River catchment, which feeds Googong Dam, is an inhabited rural catchment and extensive treatment is necessary to ensure a safe drinking water supply.

Recreational activities on Googong Dam are controlled by ACT Parks, Conservation and Lands to avoid any further contamination of the stored water.

At Googong Dam, water is drawn from the storage and pumped to the nearby water treatment plant. Treated water is then fed to Canberra's service reservoirs through the Googong Bulk Supply Main. When it was first built, water from Googong Dam was distributed to consumers in Queanbeyan, inner north and south Canberra, and the Woden/Weston Creek area during the summer months when water consumption is high. In the low consumption winter months, water from the Cotter system was used to supply all of Canberra and Queanbeyan and the Googong system was shut down.

Googong Dam supplied all of Canberra and Queanbeyan’s water in the immediate aftermath of the January 2003 bushfires, when the water quality from the Cotter catchment was poor.

The Googong WTP has been expanded to enable it to meet the average daily summer demand of the whole of Canberra and Queanbeyan. This ensures that high quality treated water can be provided should the raw water quality in the Cotter catchment deteriorate, or there is not sufficient storage volume to meet water supply needs.

The expansion was commissioned in December 2004. A parallel treatment process was added to the existing conventional treatment stream. The new dissolved air flotation and filtration process can be run in addition to or instead of the original clarification and filtration system. This addition has increased the capacity of the plant from 180 megalitres (million litres) per day up to 270 megalitres per day.

Licensing

View our NSW EPA license monitoring data for the Googong Water Treatment Plant.

The process

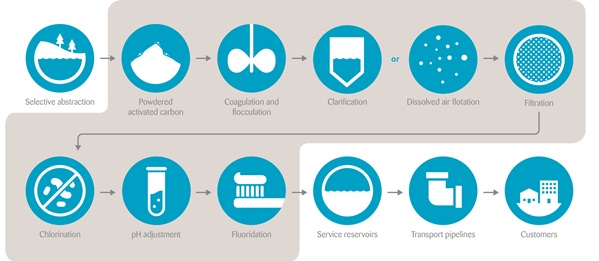

The treatment process is shown below:

Step 1 (optional) - powdered activated carbon is used for organic matter removal

Step 2 - Coagulation: substances are added to the water to encourage solid particles in the water that could host viruses and bacteria to group together to make larger particles, this is called coagulation.

Step 3 - Flocculation: coagulation results in larger particle clumps called flocs. Flocculation is a process of separating the flocs out of the water. It involves mixing and circulating the water and causing the flocs to float to the top in a sludgy froth.

Step 4 (option 1) - Dissolved air flotation and filtration (augmented plant): this optional step involves dissolving air in the water which causes suspended matter such as oil or solids to float to the surface where they can be more easily removed through the filtration process. This process is used when the raw water quality is relatively poor.

or

Step 4 (option 2) - Clarification and filtration: clarification is used to remove the flocs and followed by filtration, which involves pumping the water through filters to remove any remaining particles. Water is filtered through antracite coal and sand.

Step 5 - Chlorine disinfection: Chemical dosing to add chlorine in to the water works to kill remaining microorganisims in the water. Chlorine continues to disinfect the water as it moves through the distribution network ensuring the water remains high quality.

Step 6 - adjusting the water’s pH levels to balance it with lime and carbon dioxide

Step 7 - fluoridation by sodium silico fluoride to protect teeth (under direction from ACT Health).

Incident Response Management Plan

Download our Googong pollution incident response management plan